Urban Custom Rotational Moulding offers a complete design, build, and production service for rotationally moulded plastic products.

In-house tool design and fabrication

We can take your idea and make it reality.

Design

Our in-house design engineer uses the latest 3D Solidworks CAD design software to turn concepts into products quickly and accurately.

Mould development

Once your design is complete, we produce the mould. We use a range of mould types, depending on the project:

- Low cost, mild steel moulds for basic and semi-basic mould designs

- Stainless steel moulds for longevity and exceptional mould finish

- Cast aluminium moulds for intricate parts, longevity, and creative mould finishes

Moulds range from 100 mm through to 6 metres, in many shapes, and with single or multiple cavities.

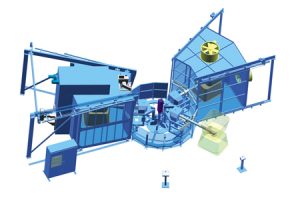

Moulding

We use only the most up-to-date roto moulding machinery to produce high quality, cost effective products for our valued customers. We can produce from an existing mould, or develop and tool new moulds to your needs.

Delivery

Your quality parts can be palletised or containerised, and delivered direct to you or your customer.

Experience pays

We currently produce thousands of parts per year across a varied customer base including waste management, automotive, marine, chemical storage, water storage, water retention/detention, and telecommunications. With 35 years of combined experience in rotational moulding in our team, there is no project too hard for us to fulfill on time every time.

Urban Custom Rotational Moulding is a member of the Australian Rotational Moulders Association (ARMA).

Call us today for a free quote and help with your product design and manufacture.